Composite Burning Rate Catalyst Purity ≥97.5% (Titration) High Quality

Ruifu Chemical is the leading supplier of Composite Burning Rate Catalyst with high quality. Ruifu Chemical has been supplying burning rate catalysts more than 15 years, can provide worldwide delivery, competitive price, excellent service. Purchase Composite Burning Rate Catalyst, please contact us by e-mail: alvin@ruifuchem.com

| Chemical Name | Composite Burning Rate Catalyst |

| Stock Status | In Stock, Large-Scale Production |

| Storage Temperature | Store Long-Term in a Cool and Dry Place |

| COA & MSDS | Available |

| Sales Strategy | Factory Direct Sale |

| Origin of Product | Shanghai, China |

| Brand | Ruifu Chemical |

| Items | Specifications | Results |

| Appearance | Brown-Red Viscous Liquid | By Visual |

| Purity, % (m/m) | ≥97.5% | Potentiometric Titration |

| Fe Content, % (m/m) | 22.5-23.5% | Titration |

| Viscosity, Pa.s (25℃) | ≤2.8 | Single-Cylinder Rotary Viscometer |

| Refractive Index, nD25 | 1.620-1.630 | Abbe Refractometer |

| Moisture, % (m/m) | ≤0.10% | Karl Fischer Method |

| Volatile, % | ≤4.0% | Vacuum Drying |

| pH | Neutral | Wide-Range pH Test Paper |

Package: 10kg/plastic drum (two plastic drums packed in a wooden case, 20 kg/case), or as requirement.

Storage: Store away from oxidizing agents and air. Keep the container tightly closed. Store in a cool, dry and well-ventilated warehouse away from incompatible substances. Avoid direct sunlight; avoid fire and heat sources; avoid moisture. Keep upright during transportation. Avoid violent collisions, avoid violent loading and unloading.

Shipping: Deliver to worldwide by air, by sea, by FedEx / DHL Express. Provide fast and reliable delivery.

Shelf Life: 24 months after manufactured date when properly stored. If expired, it should be re-sampled, re-inspection according to the technical specifications, and can still be used if retest results is qualified.

How to Purchase? Please contact Dr. Alvin Huang: sales@ruifuchem.com or alvin@ruifuchem.com

15 Years Experience? We have more than 15 years of experience in the manufacture and export of a wide range of high quality pharmaceutical intermediates or fine chemicals.

Main Markets? Sell to domestic market, North America, Europe, India, Korea, Japanese, Australia, etc.

Advantages? Superior quality, affordable price, professional services and technical support, fast delivery.

Quality Assurance? Strict quality control system. Professional equipment for analysis include NMR, LC-MS, GC, HPLC, ICP-MS, UV, IR, OR, K.F, ROI, LOD, MP, Clarity, Solubility, Microbial limit test, etc.

Samples? Most products provide free samples for quality evaluation, shipping cost should be paid by customers.

Factory Audit? Factory audit welcome. Please make an appointment in advance.

MOQ? No MOQ. Small order is acceptable.

Delivery Time? If within stock, three days delivery guaranteed.

Transportation? By Express (FedEx, DHL), by Air, by Sea.

Documents? After sales service: COA, MOA, ROS, MSDS, etc. can be provided.

Custom Synthesis? Can provide custom synthesis services to best fit your research needs.

Payment Terms? Proforma invoice will be sent first after confirmation of order, enclosed our bank information. Payment by T/T (Telex Transfer), PayPal, Western Union, etc.

Composite Burning Rate Catalyst has been used as a modifier of increasing burning rate in composite solid propellants. It could control not only the curing reaction rate but the burning rate when applied to the burning rate catalyst in HTPB composite solid propellants. It can improve the processing performance and mechanical properties of slurry, and has a good storage performance. It has been used as a modifier of increasing burning rate in composite solid propellants.

Safety Instructions: Composite burning rate catalyst could be oxidized slowly when exposed to air. Polymerized under high temperature and burned if mixed with strong oxidizer.

-

Composite Burning Rate Catalyst Purity ≥97.5% (...

-

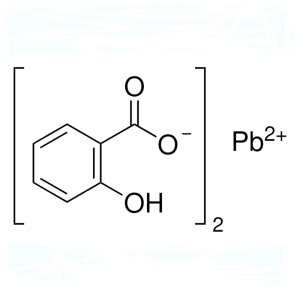

Lead Salicylate CAS 15748-73-9 Combustion Catal...

-

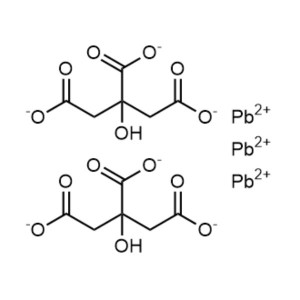

Lead Citrate CAS 512-26-5 Combustion Catalyst H...

-

Copper Chromite CAS 12018-10-9 Combustion Catal...

-

Catocene CAS 37206-42-1; 69279-97-6 Purity ≥97....

-

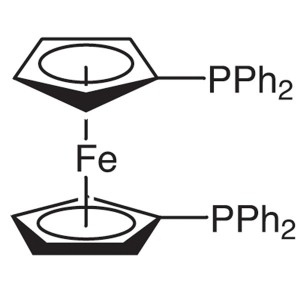

1,1′-Bis(diphenylphosphino)ferrocene CAS ...

-

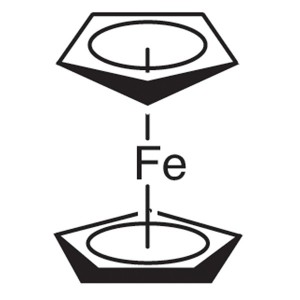

Ferrocene CAS 102-54-5 Purity ≥99.0% (Titration...

-

Octylferrocene CAS 51889-44-2 High Quality

-

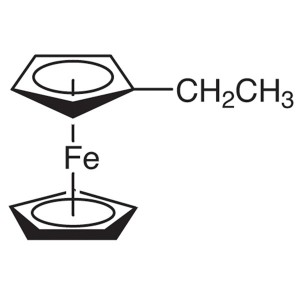

Ethylferrocene CAS 1273-89-8 Purity ≥98.0%, 95....

-

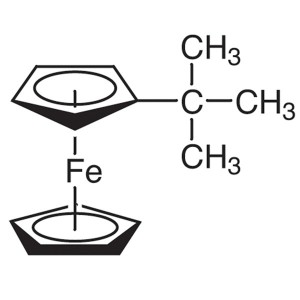

tert-Butylferrocene (TBFE) CAS 1316-98-9 High Q...